What Role Does Vertical Integration Play?

Feb 16, 2025

Fundamental changes are occurring in the satellite manufacturing industry, that undermine standard production strategies. The move toward a more modular, platform-based design strategy, instead of specific mission-unique satellites, is gradually becoming prevalent since such an approach is expected to be more efficient and flexible. This is an evolution not only a technical shift but also a reimagining of the business model and the rights and responsibilities of supply chain processes for satellite manufacturers.

Photon satellite platform based on Rocket Lab’s Electron kick stage. Credit: Rocket Lab

Photon satellite platform based on Rocket Lab’s Electron kick stage. Credit: Rocket Lab

The leaders of the industry have realized that the future is in adaptability, not specialization. Standardized satellite platforms that are compatible with various payloads have become defining characteristics of this new period in the domain of space technology. Physically doing this enables manufacturers to have a common foundation while customizing individual components to meet various customer needs, which essentially changes the economics for satellite manufacture.

The Vertical Integration Debate

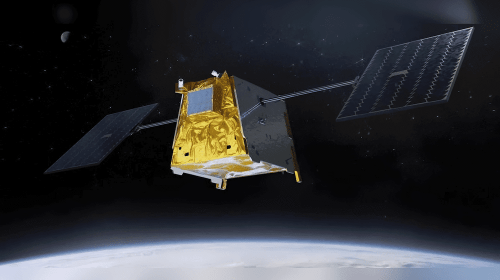

This has reignited discussions about the optimal way to manage supply chain and manufacturing control in the industry where there is a move toward standardization. Nevertheless, Rocket Lab is still relatively vertically integrated, keeping tight control over their entire production process. The reason for their strategy is rooted in a simple desire to have complete control over the quality of manufacturing and the timing of the process, given the nature of the industry, which depends on reliability.

But not everyone in the industry takes this approach. Airbus has taken a more nuanced approach, working with a network of specialized suppliers. Airbus U.S. Space Systems leader Debra Facktor stressed the importance of supply chain resilience and the value of working with specialized technology providers. This strategy enables companies to enjoy the expertise and continuous improvements of specialist suppliers without having to shoulder the entire investment and maintenance costs. Vertical integration in the space industry has its historical context that sheds light on how it developed. Industry experts have pointed out that many companies first resorted to vertical integration out of necessity rather than choice, citing the lack of specialized manufacturers in the market or the unreliability of suppliers as reasons why companies had to turn to vertical integration. From this perspective, it is argued that vertical integration should not be considered an inherently superior strategy but rather as a strategic response to certain market conditions.

The Rise of Multi-Mission Platforms

Modular satellite platforms have fundamentally changed the industry’s way of thinking when planning and executing missions. Baseline platforms with configurable options are now becoming features of modern satellite manufacturers, who now offer customers the ability to select and pay for only what they need. This approach has significantly reduced the time and cost to deploy satellites while maintaining the flexibility to meet particular mission requirements. The implementation depends on a long history of launch capability evolution. In past decades, limited launch opportunities required satellites to leverage each spacecraft to the maximum utility by utilizing multiple payloads in order to accommodate various potential needs spanning several operational lifetimes. This constraint has been lifted by the increased availability and reliability of launch options, resulting in fewer restrictions on what types of satellites can be deployed at any given time.

ULA Atlas V rocket with NOAA’s GOES-T satellite rolls out from the Vertical Integration Facility (VIF). Credit: United Launch Alliance

ULA Atlas V rocket with NOAA’s GOES-T satellite rolls out from the Vertical Integration Facility (VIF). Credit: United Launch Alliance

Moreover, this trend toward flexibility is further supported by technological advances in miniaturization and software capability. In modern times, software updates can boost the performance of satellite hardware, with the requirement for hardware additions reduced or eliminated compared to the need for complete payload integration at launch. Consequently, satellite operators have been able to optimize their fleets by combining specialized and multi-mission spacecraft in previously impossible ways.

The Future of Satellite Manufacturing

The industry has matured in the transformation of facilities used for satellite manufacturing. Airbus has moved its Florida manufacturing plant from producing identical broadband satellites to creating different spacecraft for various missions. This adaptation demonstrates the viability of such flexible manufacturing approaches to address market changes and technology requirements. This new paradigm is only as good as the maturity and reliability of its supplier ecosystem. This infrastructure has been developed and sustained by government initiatives, particularly by the Space Development Agency. The success of these investments has provided manufacturers with a more robust marketplace for satellite components and subsystems, enabling them to confidently consider a modular platform strategy.

Future professionals in the industry are likely to have to balance standardization with the ability to customize due to the continuing evolution in the industry. A balance of this nature will demand sophisticated supply chain management and strategic decisions about which capabilities to retain internally versus pull from specialized suppliers. Different forms of manufacturing have little to do with any single philosophy and are more likely to succeed (or fail) based on market conditions and mission requirements; therefore, adherence to any one manufacturing philosophy is unlikely to result in success. In addition, manufacturers must consider the emerging challenges of cybersecurity and intellectual property protection when choosing between internal or external development. With the increasing sophistication of satellite systems, rapid deployment rates, and cost demands, manufacturers are compelled to find more agile production techniques that can accommodate standardized components and new innovations. One of the most important aspects of this adaptability has been its significance for finding new market opportunities in fields such as Earth observation, telecommunications, and space-based infrastructure monitoring.

Transformative Impact of Modular Platforms

The shift from bespoke design to the use of modular platforms in the satellite manufacturing industry represents a fundamental change in how space technology is conceived, produced, and deployed. Thanks to this evolution, conventional notions of vertical integration have been challenged, and new avenues for innovation and efficiency have emerged. The success of this transformation will depend on the continued development of the supplier ecosystem, the maturation of modular technologies, and the ability to balance standardization with mission-specific requirements. As the space industry continues to develop and advance, modular platforms will likely play an increasingly important role in shaping its future.

Airbus HQ, Madrid. Credit: Airbus

Airbus HQ, Madrid. Credit: Airbus

The implications of this transformation extend far beyond manufacturing processes and reach into the space ecosystem as a whole and the future of space exploration. The adoption of modular platforms has precipitated the emergence of dedicated component manufacturers and a more diverse and robust supply chain that positively affects the entire industry. Along with this evolution has come the democratization of access to space technology, enabling smaller companies and emerging space nations to participate in satellite development without massive infrastructure requirements. As manufacturing processes become more efficient and adaptable, the cost barriers to space access continue to decrease, opening up new possibilities for scientific research, commercial applications, and international collaboration in the ongoing exploration and utilization of space.